Building a DIY Drill Press Stand give great storage for bits and other essentials. I’ve been using a little baby drill press for about a decade and I’ve outgrown it’s capacity. So when I got a new 12” drill press from JET Power Tools, the sponsor of this build, I knew it was time to upgrade my drill press stand as well to match the rest of my shop furniture.

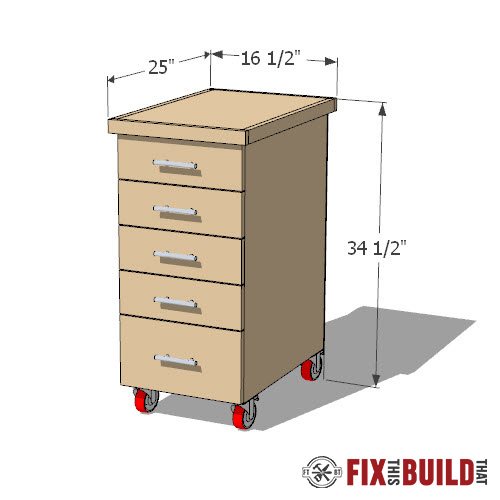

The drill press cabinet has five drawers to hold all your woodworking accessories for the drill press. It is 15” wide, 24” deep and 34-1/2” tall with castors. The drill press stand is made from just 1 sheet of ¾” plywood with a little ¼” plywood and hardwood. If you want to build your own click here to get the DIY Drill Press Stand plans.

Materials/Supplies

- (1) 4′ x 8′ 3/4″ Plywood

- (1) 4′ x 8’ 1/4″ Plywood

- (5) 22″ Drawer Slides

- 1-1/4” Pocket Hole Screws

- 1-1/4″ Wood screws

- (5) Drawer Pulls

- (4) 3″ casters

This page uses affiliate links. See my disclosure page for info on affiliate programs.

How to Build a DIY Drill Press Stand

- Build the cabinet carcass

- Build the drawers

- Mount the drawers

- Attach the false drawer fronts

- Attach drawer pulls and wheels

- Make top for the stand

- Finish cabinet and attach top

1. Build the DIY Drill Press Cabinet Carcass

The whole drill press stand is made from one sheet of ¾” plywood, just over a half sheet of ¼” plywood and a little solid wood edge banding on the top. I started breaking down the plywood for the base per my cut list.

I drilled pocket holes along the edges of the bottom panel with my pocket hole jig to connect to the sides. Then I laid the sides out on the table and clamped them tightly to the bottom with my JET parallel clamps. I secured the pieces together with 1-¼” pocket screws for a strong connection.

Then I went back to the table saw to cut the top cleats for the cabinet. I used the larger half of the full sheet of plywood I broke down earlier to get these cleats.

After cutting the small cleats to size I drilled pocket holes in each end then took them back to the cabinet for install. The cleats are installed flush with the front and back of the cabinet and flush with the top. I used the clamps again to hold everything tight and position the cleats in place and secured them with pocket screws.

Next I cut a ¼” plywood back to size to fit the cabinet. I checked the cabinet for square and with a little nudge my diagonals were the same measurement. The back is secured to the drill press stand with ⅝” screws and this locks everything into square and stops the cabinet from racking.

2. Build the DIY Drill Press Stand Drawers

I cut the parts to width for a large base drawer and four smaller drawers above it. The top drawer is slightly smaller than the others to account for the front cleat, even though the false front is the same size as the others.

Each strip I cut on the table saw gives me one side and a front or back part. I set the stop block on my miter saw stand and cut all the sides to length.

Next I measured the opening of my the drill press cabinet to get the size for the fronts. I made a full video on How to Make Easy Drawers which you can check out for more information. I go into a lot more detail about all the sizing considerations and how to deal with undersized plywood when cutting the drawer fronts.

After cutting all the parts to size, I drilled pocket holes in the ends of the fronts and backs to secure them to the sides. Assembly of the drawers is pretty straight forward. I used two sides and a front and back with the pocket holes facing outward and secured them with 1-¼” pocket screws.

After that I worked my way through all five drawers then cut the bottoms to size from ¼” plywood. I cut the bottoms to exact size and glued and nailed them on with brad nails keeping them in from the edge by about ½”.

Here’s why I shot the nails in from the edge. I added a chamfer to the underside of each drawer along the sides with my cordless router. I sized it the thickness of the bottom panel and this effectively hides the plywood bottom of the drawer when viewed from above.

Here is what it looks like before the routing, and after.

3. Mount the DIY Drill Press Stand Drawers

A few things that I’ve found to be helpful when mounting drawer slides is using consistent spacing wherever possible. For this design I worked it out that I can use just one size plywood spacer all the way up.

The spacer goes on top of the slide just installed and using a spring clamp to hold it in place works like a champ. I installed all five sets of slides, working my way up one side then the other until they were all in place.

To install the bottom drawer on the drill press stand I used a ¼” sheet of plywood scrap to prop it off the bottom. Then I pulled the drawer and drawer slides out and attached the slides with screws in two places on each side before pulling out the drawer and attaching the back of the slides to the drawer.

For all the following drawers I used spacers on top of the drawer below it so position the drawers for install.

4. Make and Attach the False Drawer Fronts

The false drawer fronts are cut from one continuous piece of plywood. I cut each drawer front to size with the top four all being the same height. The ⅛” blade kerf is the same as the reveal between the drawers, so the grain on the front will look like one flowing piece.

Before attaching the drawer fronts I sealed the cabinet and drawer fronts with water based polyurethane. I left the drawers unfinished since they are shop drawers.

To attach the false fronts I drilled mounting holes in the front of each drawer.

Then starting at the bottom I used a ⅛” spacer and stacked the drawer front on top of it. I clamped it in place and secured the drawer front with panhead screws from inside.

I followed the same steps working my way up the DIY drill press stand. I’d just stack the ⅛” spacer on the drawer below it, line up the sides with the cabinet sides, clamp it in place and secure it.

5. Attach Pulls & Casters to the DIY Drill Press Stand

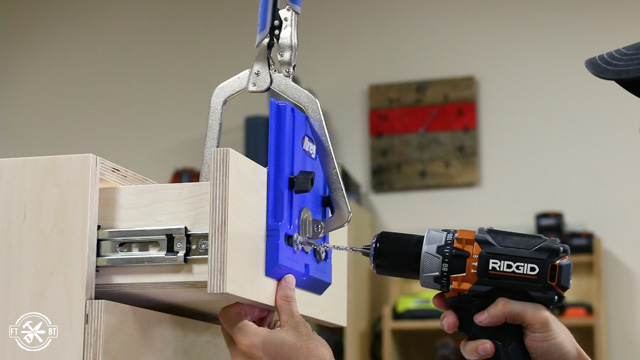

You can mount the drawer hardware a lot of different ways. I like using a cabinet hardware jig I can clamp to the drawer front and drill two holes spaced for the hardware I’m using.

Starting with the top drawer, I drilled the holes then screwed the handles in place with the included hardware. After that I quickly work worked my way down and the base was almost done.

To finish off the base I took the drawers out then flipped the drill press cabinet over on it’s top on the floor. I used 3” double locking casters and attached them at the corners. The mounting holes that are over the sides of the cabinet get 1-¼” screws but the ones on the inside get ⅝” screws.

6. Make the DIY Drill Press Stand Top

The last piece of the DIY drill press stand is the top. I cut a piece of ¾” plywood down to the width I wanted but left it about 2” long. Then I drilled pocket holes along each side to attach the trim.

The edging for the top is birch hardwood that I cut to 1-½ wide pieces on laid on edge. I glued and screwed the strips to each side of the top, clamping both the edging and the top firmly to the workbench. And I also made sure the screws were well within my final length.

The reason I left the trim and top piece long was so I could cut them to size on the table saw and everything would be flush with no fuss. It’s just one less measurement to worry about when trying to edge band a plywood top.

After cutting the top to length I drilled more pocket holes on each open end for the top. You could also use biscuits or dowels here for alignment, I just like the speed of pocket holes since you don’t have to wait for the glue to dry. The ends are attached the same way as the sides with glue and screws on each end.

7. Finish and Attach the Top to The Drill Press Cabinet

I added a roundover to the edges of the top then sealed it with polyurethane before mounting. Then I cut a couple mounting strips to attach to the underside and I got a chance to test out my new 12″ drill press from JET.

The two things I’m really excited about with this drill press are the added capacity over my old one and the digital readout and variable speed. Instead of fooling with belts you can just turn a lever and adjust the speed on the fly.

I attached the strips to the top then screwed the top down from underneath through the cleats installed on the cabinet.

The top drawer will hold twist and brad point bits. And the 2nd drawer will be my forstner and other specialty bits. Leaving 3 more drawers for clamps, hold downs, vises and whatever else I can think of.

If you want PDF plans on how to build this drill press cabinet just go to the DIY Drill Press Stand Plans page. And if you want more great shop projects you can head to my Shop Projects page.

JET Power Tools provided me with product and/or monetary compensation as a sponsor of this build. All opinions are my own and are not filtered by the sponsor.

Vibrations have never been an issue for me. I have the drawers loaded up so that may help.

I like the cabinet and I like the Jet 12″ drill press. However, I have the same one and it does create a lot of vibration on the cabinet. How did you deal with that? I use a old cabinet with drawers added and then placed 2 cement blocks in the bottom area to give the cabinet some weight to dampen the vibration. It takes up valuable storage space but it does cut down on the vibration.

Dave Sanek

Why the ¼” holes to attach the false fronts to the drawers?

It leaves room for a little bit of adjustment in case you don’t get it perfect

I built your drill press cabinet and I’m happy to say it turned out great. Thanks for the plans, which were very detailed and provided all the info necessary for a successful build.

Glad they worked out for you!

I love this design. I am, however, concerned about the center of gravity being so high. (My very active young grandson is often in my shop.) Is there some type of easily retractable brace to lower the CG that I can add?

Very nice build but the overall height seems a bit much for a 12″ drill press unless you are a really tall dude. Wouldn’t taking out one of the middle drawers out gives a more comfortable height for drilling (29 3/8 instead or 34 1/2)?

I modeled the height of the cabinet off of the height of a larger floor standing drill press. The height is great for me, I like it. If you want to adjust it to make it lower you can.

Thanks. I think that a lower height will be more comfortable for me. If I got the calculation right, I’ll need to take 5 1/8″ off the height of the side and back panels. Everything else is the same.

Just wanted to say thanks for this. Built it Labor Day weekend. Your plans and the video made it very easy for me, a fairly new woodworker, to build. I see you’re in the Nashville area too. Know any good placed to get lumber? Thanks again.

Awesome, glad you enjoyed it! Try Mimms Lumber!