Plans for a Mobile Miter Saw Station

Today I’m going to show you how to build a mobile miter saw station. I’ll give you a full walk-through and I also have the miter saw stand plans for you too. This project is going to give your shop workhorse tons of flexibility, plenty of work support, mobility, and a ton of upgrades. This miter saw table is a great addition to any garage or workshop short on space. The plan will fit most miter saws, but the measurements could be modified to fit other tools or saws as needed.

***Update, I’ve now added a YouTube video on this build and added a few small tweaks, make sure you check it out below! ***

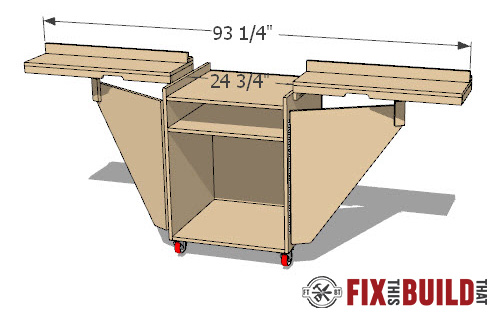

The Mobile Miter Saw Station is made from 2 sheets of ¾” plywood. It is 39” tall on 3” casters and with side wings extended it’s 93” wide. When stored it’s only 38” wide and 24-½” deep, because the folding wings give it a small footprint.

I made several upgrades to the DIY miter saw stand plan to give it added performance and usability. A basic version built out of common plywood can be made for right around $100. But upgrades such as better plywood, larger casters, dust collection, an automated vacuum switch, and an aftermarket fence and stop system can make this build a workshop masterpiece.

Materials/Supplies

- (2) 4’x8′ 3/4″ Plywood

- 1-1/4″ pocket hole screws

- 1-1/4″ wood screws

- 5/8″ wood screws

- 72″ long 1-1/2″ piano hinge

- (2) 1/4″-20 20mm threaded inserts

- (10) 2-1/2″ 1/4″-20 bolts

- (8) fender washers

- (8) 1/4″ flat washers

- (2) 1/4″ wingnuts

- (8) 1/4″ lock washers

- (8) 1/4″-20 threaded knobs

- See upgrade list

Affiliate links are used on this page. See my disclosure page for info on affiliate programs.

And if you want to get a great deal on two spacing-saving shop plans, check out the Flip Top Tool Stand and Miter Saw Station Combo Plan pack and save 33%!

How to Build a Mobile Miter Saw Stand: Part 1

- Assemble the Base

- Make the Side Wings Supports

- Mount the Side Wings Supports

Assembling the Miter Saw Stand Base

Start by drilling pocket holes on the underside of the left and right edges of the shelves. Secure the top shelf while using a right angle to hold it square.

After that secure the other side to the top shelf using the same method.

Attach the middle shelf to each side 5-¾” down from the top shelf. Using a bar clamp while you work to hold the sides together is useful here.

After that screw the bottom shelf in place flush with the bottom of the sides.

Check the miter saw cabinet for square by measuring from corner to corner, first from the bottom right to top left and then from the top right to bottom left. The cabinet is square when the measurements are equal.

Cut a back piece to overlap the sides, top shelf and bottom shelf which will also square the case. Tack the back in place at two corners with a 18ga Brad Nailer and then secure with 1-¼” screws around the edges.

If you’ll be adding dust collection to your DIY miter saw stand, then drill holes for the vacuum hose and the power cord in the back. I drilled a 2-½” hole for the vacuum hose and a 1-½” hole for the power cords in the back because it’ll be a cleaner install this way.

Flip the cabinet upside down and mount the casters on the bottom corners. After that use 1-¼” screws into the sides and back and ⅝” screws when attaching only to the bottom shelf.

Making the Miter Saw Station Side Wing Supports

Next you’ll make and attach the side wing supports for the DIY miter saw stand. Make a diagonal cut from the top to the bottom as seen in the picture. I used a 5” spacer (the width of my circular saw base plate to the blade) to position a straight edge for the cut. While out in the driveway I also cut off the bottom to remove the pointed end.

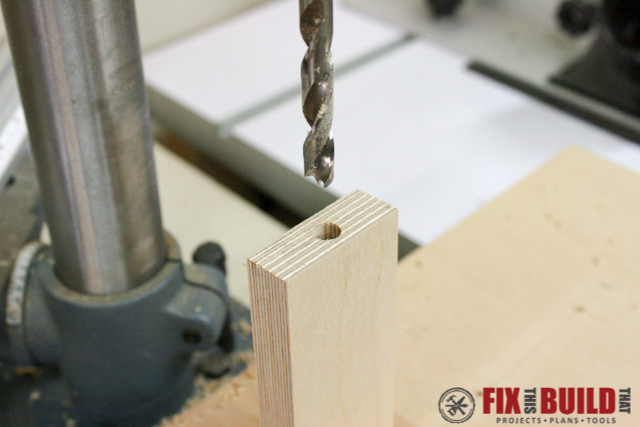

Next I cut two support riser pieces. These will hold 2-½” hex head bolts and wing nuts used to level the side wings when the miter stand is done.

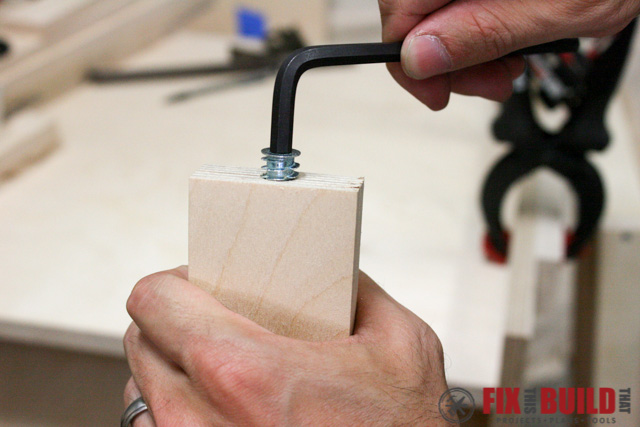

Using a hex wrench, screw in a ¼”-20 x 20mm insert nut into the ⅜” hole. And finally install the hex bolts and wing nuts to finish the assembly.

Next attach the support risers to the side wing supports with glue and 1-¼” screws. The risers should stick up 1” past the side wing supports and be flush with the outside edge of the side wing support when installed.

Cut two 25” pieces from a 72” long 1-½” piano hinge using a hacksaw or a reciprocating saw with a metal blade.

Center the hinges on the long edge of the side support wings and attach them with ⅝” screws. To make mounting easier, lay the hinge over the edge and hold it tight against the corner while attaching the screws. Make sure you’re attaching it on the opposite side of the support riser.

Mount the Miter Stand Side Wing Supports

Mount the side wing supports to the miter saw stand base 2-¾” down from the top with ⅝” screws. The supports should be flush with the front of the base when fully open at 90 degrees. Use pieces of wood clamped to the supports which help position it flush with the front of the base as seen in the picture. Have a helper hold the wing while you secure it.

On the next post we’ll make the fence, mount the saw and install all the upgrades when we finish the Mobile Miter Saw Station.

Mobile Miter Saw Station Part 2: Side wings, fences, and upgrades

RIDGID provided me with tools and/or monetary compensation as a sponsor of this build. All opinions are my own and are not filtered by the sponsor.

I LOVE my Mobile Miter Saw Station, SOOO handy. I just discovered I needed a sliding chop saw. Unfortunately it will not fit the Miter Saw Station top 🙁 ANY SUGGESTIONS?

I had a Porter Cable 12″ Compound (model 3802L) and just purchased a Dewalt Compound 12 ” Slider (model DWS779).

thanks

I know this is old, but I just built this for my DSW779. I cut 8″ slots on either side to account for the carrying handle embrasure thing, then had to knock out about 1/4″ on one side in the plywood. I used a wood chisel and it worked perfectly. Slid right in. If you want, I can send you some pictures.

Brad, where did you get the cyclone and did it work for you? Was the small vac strong enough? Getting ready to build this – just gathering all the pieces. Thanks buddy!

Bob

At one point you say to check the cabinet for square by measuring from corner to corner. If it isn’t should we try to “tweak” it back in…I tried and it is pretty tough to do. Afraid I would break something. Suggestion???

Great detail on your Miter Saw Station plans and video – thank you.

I have a new issue – the steel pins are falling out of the hinges – any suggestions?

Thanks again, I plan on making “Fred” next 🙂

Bradley

Never mind I ticked the bottom end slightly with side cutters…easy.

Nice fix! Have fun making your own Fred 🙂

It seems as though using the shims and 4 foot level across the chop saw deck is a whole lot easier and safer than trying to get the levelness precise during the placement of the top shelf. Is that why shims are used to set the deck level?

Anyone ever try to get the height correct without using shims…

thanks

Bradley

Yes, that’s exactly why I did it that way. Too difficult to nail it exact!

You can also buy a cabinet at your hardware store then just add wings

Has anyone built this for a Dewalt DWS780. It’s a sliding compound miter saw. The base is 26″ wide. Curious to know what kind of adjustments you made.

same question here. I have the DWS779 which is nearly the same saw and it’s a beast. Takes up a ton of real estate to be able to get full extension in all directions. I think I’m going to use the wings idea but build it onto a dedicated cabinet/workbench with more traditional 2×4 frame…maybe.

Yes I widened the top and lowered the base. I also added all thread with nuts and washers to exactly raises the Saw surface to match the wings. ( my math was off by 1/16” )

Brad,

When adding the shims, do you make sure that each wing is level and then put the 4ft level across to figure out what size shims you need? Does it matter when you put the 4ft level on that it’s not level?

Do you use freedom units or metric in your plans?

Freedom units (aka imperial)

Wondering what everyone is doing for surface finishing. Paint? Stain? Poly? Bare wood?

water based poly for me

Just finished mine! I plan on putting a couple of drawers in it instead of the Shop Vac. Cutoff bin on the bottom, blades and other small stuff in the top. Thanks, Brad! Great plan.

My most awesome project for my workshop. Thanks. Miter saw is my most used tool, and to have this versatile stand for it makes it a pleasure to use. Big thanks for the plans!

Hey Brad,

I bought your plans and am close to finishing. What are your final thoughts on the 4 gal vs. the 12 Gal. Vac? Its time for me to buy one or the other. will the 4 Gal do the job? DD

I’d go with the 12. the 4 gal just doesn’t get enough suction.

Purchased your plan when you first built. I added a drawer under the saw. Works great for me. I like your page Thanks for all your Idea’s

Hi Brad.. I purchased your combo package for Miter saw and flip tool Stations.. My miter saw is only approximately 19 inches wide Should I adjust width or will it cause a balance issue if stand is to narrow.Thank you

Anthony

Great post Brad, one question: how well does the dust collection work? The link to the 2 gallon vac at HD doesn’t work when I click on it, btw.PS VERY impressed by charging station you built a few weeks ago – Arduino – wow!

OUTSTANDING plans. I made a few small alterations to fit my bench top router table in. Now the one cart is perfect for both my miter saw and my router table. Thanks

How does this work with a 12″ dual bevel sliding mitre saw? Thats my saw and I am concerned about the sliding rails sticking out the back.

Great project, great plans. Mine should be finished this weekend.

Awesome! Hope you love it!

Helpful hint to everyone building one of these, make sure you measure the height and width of your saw before you start. 🙂 I’ve had to make a few alterations to make it work. I have the larger sliding miter saw from Rigid, and like a novice I just assumed since Brad used a Rigid Saw it would have the same dimensions. Other than that, I absolutely love this stand. I went with all of the upgrades and it is amazing and worth every penny.

What grade/kind of Plywood did you use?

Do you have a combination plan that combines the miters with the planner flip top? I’d love to buy the plans to make a single stand to handle both my tools

I need a stand for my miter saw and this one looks good. My shop is small so the folding wings will work well

awesome, enjoy it

Did you have any issues with the iVAC automated outlet? I’ve read that it only handles low amps and that It trips really easy… I have a shop vac and am worried it will be too much for the outlet – how did your rigid do with it – their amperage is similar if you use the one you advertise in the tool list

Did you have a video of you making the miter saw station?

Unfortunately I don’t. It was before I started shooting video.

Just got a Dewalt DW716 and am going to build this station for it. It looks like your Ridgid saw has similar slide out fences as the Dewalt. Are these accounted for in the plans? Or do you just need to lower the wing on the side of the fence you’re sliding out to make a bevel cut?

Good question. I’ve never had anyone tell me they’ve had issues with that feature so I’m assuming it’s not a deal breaker. The saw widths will be different too, so I don’t know how much room you will have to slide the fence, but I can slide mine about 3″, which depending on the angle usually gives clearance. Worst case I remove the fence or lower the wing. But honestly very very rarely make bevel cuts on the miter saw.

My saw is just under 24″ wide so I thought about adjusting the size slightly. I can make it a bit wider to allow for the wings but should also be able to just drop the wing on the side I need to slide out and still get support with the other wing up. I’m also planning on making the fence adjustable back and forth so I suppose I could always move it back if need be. Thanks for the response!

A BIG word of advice for anybody planning to build this: measure the height of the platform of your miter saw first. These plans are setup for miter saws where the top of the miter saw is shorter than 4″ tall. I’m really close to finishing this project for my Ridgid MS1290LZA and I just realized that the platform for my saw sits like 4-21/32″ high. So I can’t shim my saw up to the level of the side wings because it’s already too tall. I need to either raise the side wings or lower the top shelf on my build. Love the design still, just something to think about before anybody gets too far like I did. Thanks Brad.

Thanks, Josh. I’d suggest lowering the top panel would be easiest. I will go back and update some of the verbiage to make sure people understand this very clearly.

That’s what I ended up doing. Came out great. Thanks for the excellent plans.

Will this work with the R4221 as well?

With your shop vac begin a single phase do you use the filter in it when using with the miter saw?

I built this mobile miter saw station, both parts one and two. I love it. i don’t have it set up with the vacuum yet but i store my Dewalt 10″ table saw in the bottom section. It fits perfect and both saws are readily available. I work in my garage and have to put everything away each day so it makes it very convenient and easily mobile. Thank you so much for the plans.

Michael, I’m glad you are enjoying the build! Thanks for the feedback.

Any way you can see to combine this with the flip-top cart? Trying to figure out logistically if it would work.

Yup! Check my Instagram feed. I’ve posted at least 2 that reader’s have combined. Should work great!

Nice thank you!

Good afternoon Brad. Wondering what the best type of plywood I can find at my local Home Depot would be for this project? Thanks!

Allen, I’d suggest using the Purebond plywood. They should have it in 3/4″ maple or birch. It’s the best they have.Brad

Hi Brad. Looking forward to building this. Unfortunately, I’m unable to find the long 30mm threaded inserts…anywhere. The longest 1/4″-20 threaded inserts I find are 20mm. Any suggetions for finding the 30mm inserts?

Jim, I got them off the shelf at Home Depot in the bagged hardware section.

Brad – love your projects. Where do you get the orange casters? Have searched everywhere! Thanks!

Thanks, John! Got them at my local Woodcraft.

Brad, Is there an actual PDF plan with the cut list?

Yup, go over to Part 2 and it’s right there

I have a question, I have a slight problem that I’m hoping you have alternatives for. I do not have a Brad Nailer at this time and cannot afford to add another tool to my shop anytime soon. What can I use in place of the Brad Nailer? Have checked and in my local area they do not rent them. I know owning one would be a tremendous tool to have, just on a low fixed income, the power tools I have have been gifts, or inherited from my Pop.

Marianne, you can easily do without the Brad nailer. I just used it to secure things in place before screwing them in place. But you could just use clamps to hold things in place while screwing them down. If that’s all you’re missing then don’t worry about it!

Thank you… I have one sheet of plywood in my garage shop, next month I’ll get the second and a few of the other items.. casters and hinges .. I really need a stand for my miter saw, love that this has everything I need in one!

Is tihs an original design? It looks very much like one I built from Fine Woodworking

Hey, Rob. Most miter saw stations are going to look pretty similar just because there are only so many ways to do it. I used some of the same design features as others out there, but my design is different in several ways such as the moving and detachable fence, the side wing design, and the pocket hole joinery. I made sure I wasn’t copying other plans when making this.

Brad, I am really glad I started subscribing to your site. This project is just what I need. Everything in my shop I have built a base with casters so everything is mobile EXCEPT my sliding compound saw. I love this because it is a compactible, one unit design. Thank you.

Glad you like it and thanks for following along!

I plan on making this soon. Quick question, what size wood screws did you use? #6, #8, #10?? Thanks!

Mike, I used #8 for all of these except I believe the hinge screws were #5 or #6.

I need one! It would make me so much more efficient in the workshop.

It is a really nice addition to the shop!

Great job! I need to build one of these, I have the saw and it needs a home. 🙂

Thanks, Amy! It already making a world of difference. I highly recommend making one!