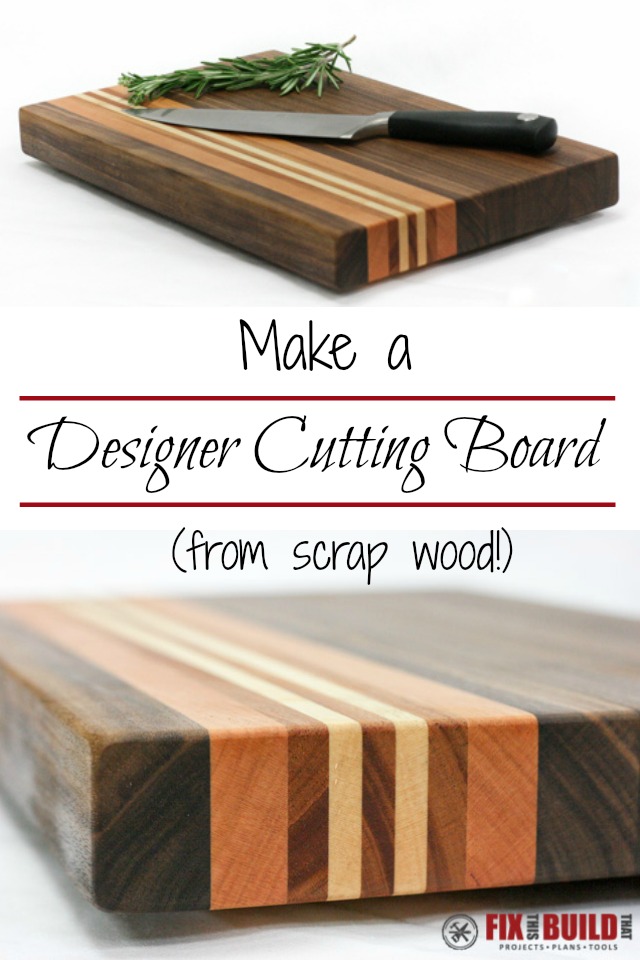

Today I’m going to show you how to make a cutting board from any wood. I’m using leftover scraps as it’s a great use for those skinny odd length offcuts you have hanging around your shop. Depending upon the scrap wood that you have, the design possibilities are endless, and of course you can buy wood specifically for the project to get exactly what you want.

I’m making a thick edge grain board today, but you can also make face grain and end grain boards with all kinds of designs. I also have a post on How to Make an End Grain Cutting Board that you can check out as well.

Materials/Supplies

- Hardwood scraps (or new)

- Mineral Oil

- Beeswax & Oil Blend

- Wood Glue

- Glubot

- Glue brush

- Sandpaper

Affiliate links are used on this page. See my disclosure page for info on affiliate programs.

You can make a cutting board in 5 easy steps

- Prep the stock for the DIY cutting board

- Layout the cutting board design

- Glue-up the wooden cutting board

- Final shape the cutting board

- Sand and oil the DIY cutting board

1. Prep the Stock for the DIY Cutting Board

These are the outcast boards I wanted to find a use for. I had 2 long offcuts, one of cherry and one of walnut. Then I had a thicker piece of mahogany and a small scrap of maple. All the boards were about 1″ thick and all but the maple were at least 1-3/4″ wide. Perfect for making a cutting board!

The maple piece was 16″ long, so the first thing I did was to cut everything to 16″ chunks. I used my Mobile Miter Saw Station for this and just set the stop block at 16″ and went to town. Use whatever size you have available or the size you want your boards.

The side supports on the Miter Saw Station really came in handy on the 10′ walnut piece!

Lay out the cut pieces and start thinking about what kind of design you want when you’re making a cutting board.

Next make all the pieces approximately the same width. I set my table saw to 1-7/8″ (a little wider than the smallest piece of maple) and ripped all the boards down to that size. Again, use whatever width you have. I recommend staying above 3/4″ to keep away from warping.

2. Layout the Cutting Board Design

For my cutting board design I wanted to have full sized walnut pieces with stripes of accent wood on one side. For small strips, use a bandsaw or table saw to cut the scraps downs. I went with 2 small strips of maple and 3 strips of mahogany.

Do another rough layout of the cutting board to see the design start coming together. My cherry pieces were still too wide, but I’d address that later.

Flat and smooth gluing surfaces are a must for good cutting boards. Run each piece through the planer on both glue faces until they are smooth. I ran the cherry through several more times to thin it out. Yeah, that’s the ticket!

3. Glue Up the Wooden Cutting Board

Now it’s time for the part I get the most questions about; the cutting board glue up. I use Titebond II when making my cutting boards. That’s all you need to hold things together. No dowels, no biscuits, just the wood glue.

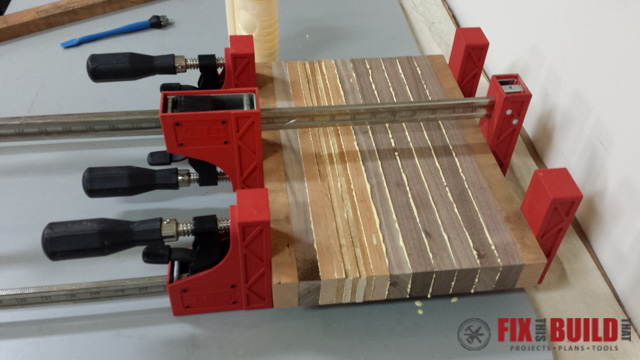

Lay the boards on your clamps with some clamping cauls between the end boards to be glued and the clamp faces. This helps keep dents off the finished cutting board and spreads the pressure evenly.

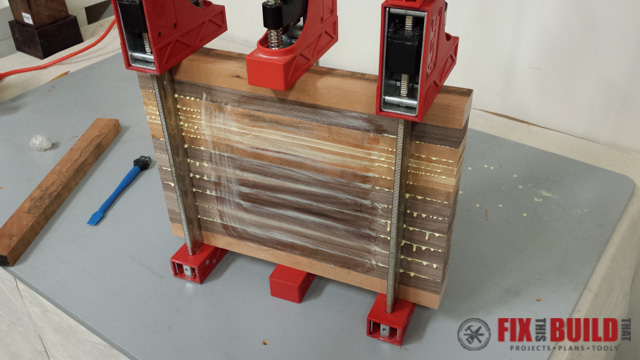

Flip the boards over one by one and put glue on one the planed faces and then stand it back up against the other pieces. Use a glu-bot bottle and glue brush to save some time. Make sure as you tighten down the clamps you adjust the boards as needed to keep them flat and even. Here’s what the final clamped glue up looks like.

I’ve started taking a wet rag and wiping up as much of the wet glue as I can. This is way easier than scraping the hardened glue blobs off your cutting board later.

4. Final Shape the Cutting Board

Next take the cutting board out of the clamps and send it through the planer using a skip-planing method. That’s a fancy way of saying flip the board end for end at each pass. Do this until you have fresh smooth wood on each face.

Then trim the ends of the cutting board to make them clean and get your final size. I used a crosscut sled on my tablesaw for this. Do you need to make a crosscut sled? Check out my free plans and full video tutorial

If you want to put a decorative edge on your cutting board then do that now using a roundover bit in a router. I prefer a very small roundover on my cutting boards that I mostly do by hand, but sometimes I’ll go with a chamfer if I’m feeling macho that day.

5. Sand and Oil the DIY Cutting Board

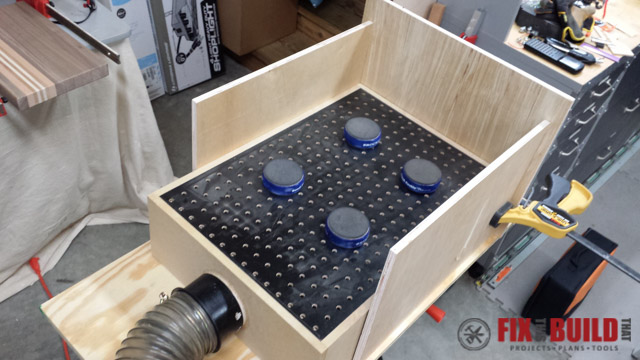

Now it’s time for sanding…ugh. This is the sanding station I use when I’m making a cutting board. It’s a Downdraft Sanding Table Box I have plans for, so check it out if you want dust free sanding.

I start at 100 grit and work my way through 150, and 220. At 220 I spray the whole cutting board down with water and wipe it off. This is known as “raising the grain”, and basically you are making the cut wood fibers stand up so you can knock them down for a smooth feel. If you don’t do this then the first time you wash your cutting board it will feel very rough.

After the cutting board dries, hand sand it lightly with 220 until it feels smooth again. Wet the cutting board one more time and hand sand with 220 again. Now when you wet the board after use it will still feel smooth to the touch.

Finish it off by sanding with 320 grit and 400 grit by hand for an ultra smooth cutting board.

And now for everyone’s favorite part of making a cutting board, applying the finish. I almost always use straight mineral oil followed by a beeswax and mineral oil blend. Nothing special for the first coat, just any ole mineral oil you can get at the drug store or grocery. Pour on a big puddle of mineral oil, then sit and stare at it. No seriously, you are going to be mesmerized by how amazing your cutting board looks.

Okay, now snap out of it and spread the oil around. Let it sit for about 5 minutes then wipe off any excess. Repeat this process with 1 more coat until the board is nice and saturated. Then I top my boards with a beeswax and mineral oil blend that helps with extra water protection and lets you buff your DIY cutting board to a nice sheen.

Oil the board whenever it starts looking dry by just applying more mineral oil. The rule of thumb is to do it once a day for the first month, once a week for the next month, and once a month there after. I totally don’t do that. If it looks dry, I put more oil on it 🙂

And that’s it! Now you know how to make a cutting board out of any type of wood. You can add feet, hand holds, juice grooves and all types of other things to cutting boards, but I like them simple. I leave the feet off because then you can use both sides.

I also have posts that show you how to make an end grain cutting board and a curved cutting board using bent lamination. If you build a board post a pic of it in the comments so I can see it!

Thank you for sharing and an enjoy to read along with!

Looking forward to the beginning of a wood business!

What are the final dimensions of this cutting board?

Hey, Brad. I love this. I about to attempt this great build and I have two questions:1. If I use boards finished on four sides instead of offcuts, can I get away without the planer and just sand?2. Where did you get the 5″ hand sander pad? I can’t find it anywhere!Thanks so much and great job!

I built a cutting board using these steps and it came out great! however after a week I noticed it started to warp in the center. any ideas on why that could have happened? I used walnut and maple.

Did you leave it flat on a surface with any amount of water under it? That is a very common reason warping happens. Or it may have had stresses in it that started moving after milling. Best bet is to let the wood sit after milling for a few days and that will help. And then again, sometimes it just moves in a different humidity level. It’s a small mystery at times.

Great site, really love all the info and plans you put out. I’m currently making two cutting boards from walnut and a few maple strips. They’re about 12 x 18. One issue I’m having that is perhaps more about how to use a planer than make a cutting board, is chip out. When arranging all the strips for the edge grain face that’s going to show, care should be taken to be sure the grain is all going in the proper direction so when you feed it through the planer as a glued up panel you don’t get random strips that chip out when the rest of your strips are perfectly fine. I had to basically choose the direction that gave me the least amount of chip out, and then I’ve been doing a TON of sanding after the planer. Really new to Woodworking and this is my first planer I have ever had I just thought this was a good point to bring up that I haven’t really seen people mentioned in their YouTube videos or their cutting board books. Keep up the great work

Yup, that’s definitely something to watch out for when you are doing a face grain board. When doing edge grain boards it is a little easier to deal with because the pieces usually don’t have as many grain issues that way. I have the luxury of using a drum sander after my planer so I don’t worry about it. But if you are getting tear out on the planer you can try smaller removal per pass and also slightly wetting the wood before planing. Post a pic when they are done!

hi. do i need to apply sanding sealer on the wood?

mineral oil is all you need in order to be able to finish the board? Is it dish washer safe? Also, what if I choose to stain the wood first, are there extra precautions I would need to take? I’m completely new to woodwork so these might be stupid questions. Thanks for this tutorial by the way!

Ashlyn, no worries, glad you are asking the questions! Stain is a big no-no as well as dishwashers. I just use normal mineral oil and only hardwoods like walnut, cherry, maple, etc. These don’t need stain to look beautiful. Clean it by handwashing with warm water then let dry on edge.

Thank you so much for the response! Very helpful!

what are all the demensions?

Extremely nice pattern. I was thinking of making these and selling them during the summer. I would be using maple, walnut, and red oak. My dad has a shop to mill everything. My question is what should I charge, is $30 too much?

$30 is far to low in my opinion if you are making it with a nice finish and the same dimensions as mine. Check Etsy to see what others are selling for. You could go to 40 or 50 with nice designs.

I urge you to NEVER use pallet wood for anything that will touch food. You never know what the pallet was used for. It might have been used for chemicals or poisons.

I would never use pallet wood. All this wood is kiln dried cutoffs from millwork stock.

Nice board indeed. I have 40 Rhodesian Teak planks 2.4 meter x 95 mm x 32 mm. Should I cut the 95 mm in half to use the edge grain. This will be my 1st board

That’s how I would do it! Then you have a nice thick 1-1/2″ board (for us Americans) 🙂

Love your tutorial.

Nice cutting board! Do you get snipe when running the glue faces through your planer or skip planing?

I get a little snipe here and there. But I’ve got my planer pretty well tuned at this point.

That’s great! I get snipe so I’m trying to figure out how to tune the planer or whether there’s a workaround using sacrificial scraps ahead of and after the cutting board. Maybe you can do a blog entry on planing some day?

That would be a good one!

Love this! Seeing the wood come to life from the mineral oil is my favorite!

Oh yeah, that is the best part for sure!

Goodness Brad, this piece is so gorgeous! The tones are simply outstanding. I think this needs to be mass produced!

Thanks, Donna! But I have a hard time making something the same over and over. All my boards tend to be slightly different to keep it fresh for me 🙂

It’s beautiful Brad! I have been wanting to make one of these for a long time, maybe someday, great tutorial!

Thanks, Mindi! You should totally make one.